Quality Control

About

Feedback

Address:

No.1055, Bazi Road, Xiuzhou Industrial estate, Jiaxing City, Zhejiang, China. 314000

Tel:086-573-82753050

Fax:086-573-82795661

Website:www.xj573.com

Email:info@xj573.com

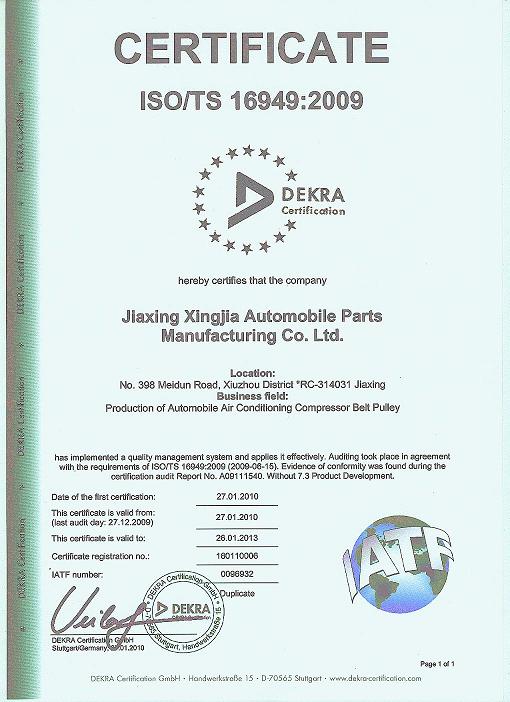

Quality Control

The goal is zero defect.

Jiaxing Xingjia automobile spare part manufacturer CO.,LTD. everyone is concerned with qua lity. The Quality Control Department keeps a history of all manufactured parts through inspection records and sample pieces. Statistical Control charts are used to study the efficiency and capability of a manufacturing process and to achieve zero defects in the process.

lity. The Quality Control Department keeps a history of all manufactured parts through inspection records and sample pieces. Statistical Control charts are used to study the efficiency and capability of a manufacturing process and to achieve zero defects in the process.

In Coming Inspection

All raw material are certified by our suppliers and must pass in coming inspection before they are released for production. In some cases raw material samples may be sent to independent labs for special testing to meet a customers demands. All raw materials are marked so they may be traced to their original certification at any time during production.

In Process Inspection

All phases of production are monitored by in-process inspection. A first-piece inspection is always conducted at each manufacturing stage. No production run begins until a first-piece inspection is completed and the results are found acceptable by the Quality Control Manager. Each machine operator performs continuous inspection while producing the parts, checking dimensions with gaging tools as well as observing the appearance and surface characteristics of the part. A inspector periodically audits samples of the product from each machine, taking samples at designated time intervals

Final Inspection

No order leaves the Xingjia Metal Products shipping dock until all shipping papers are stamped and signed by the final inspector. The goal of our quality control program is zero defects in 100 percent of all finished parts.

|

|

|

|